The digital toolbox for any factory.

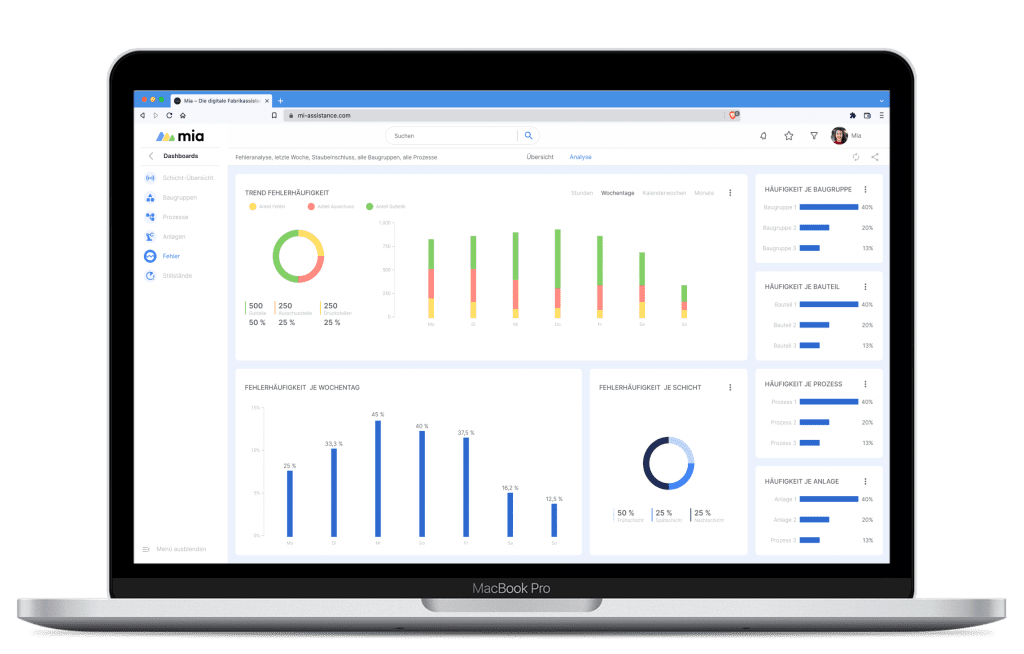

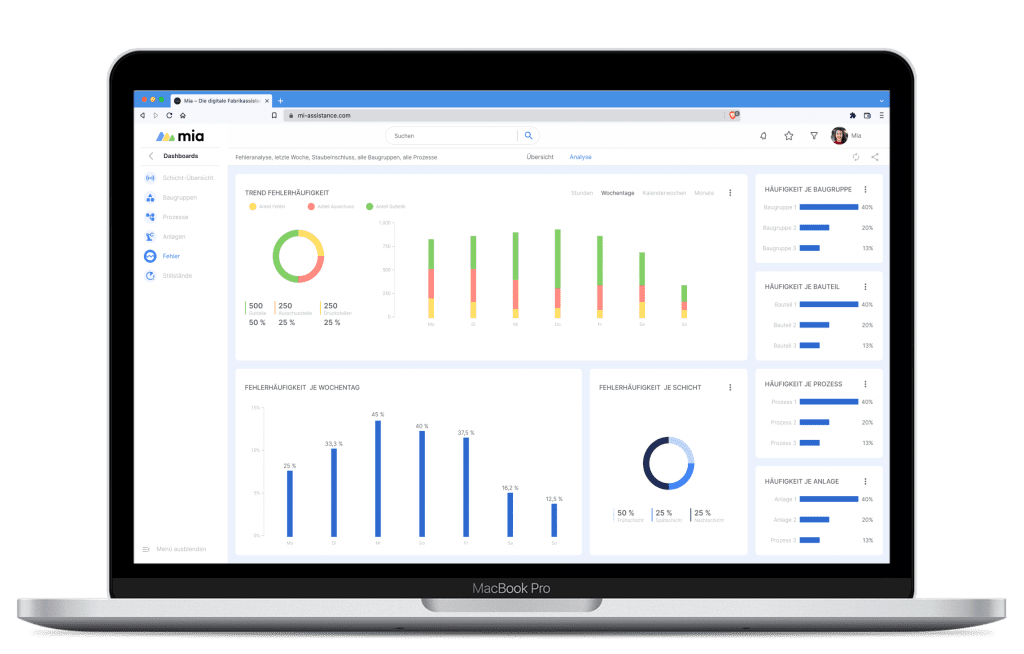

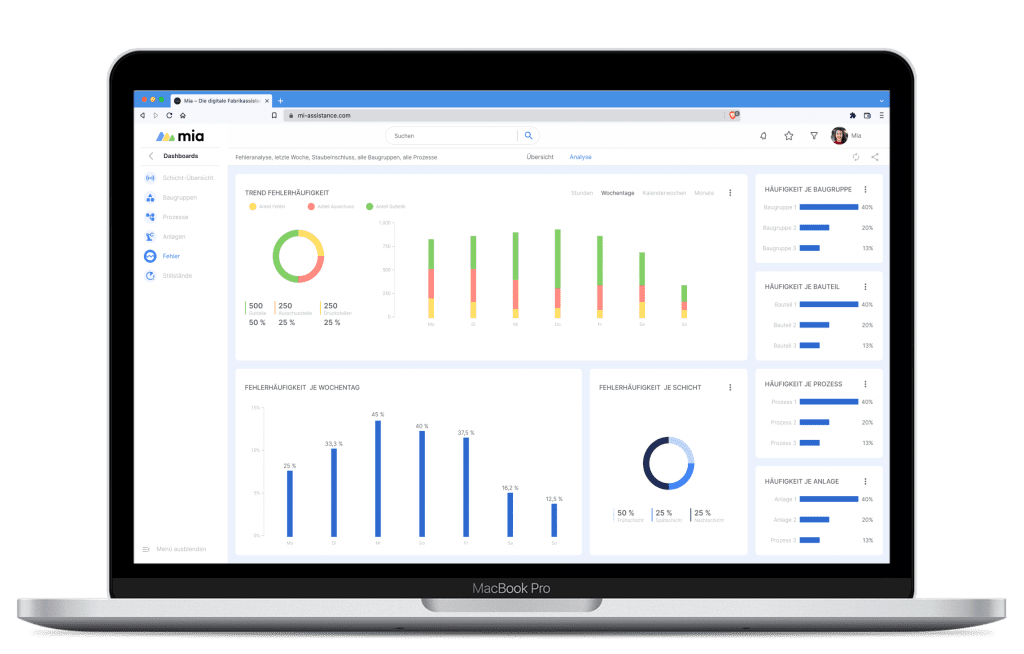

Understand new problems quickly.

With the help of various evaluations, mia supports your team in analysing the causes and helps to identify correlations. In addition, with mia you can easily check the effectiveness of measures over time.

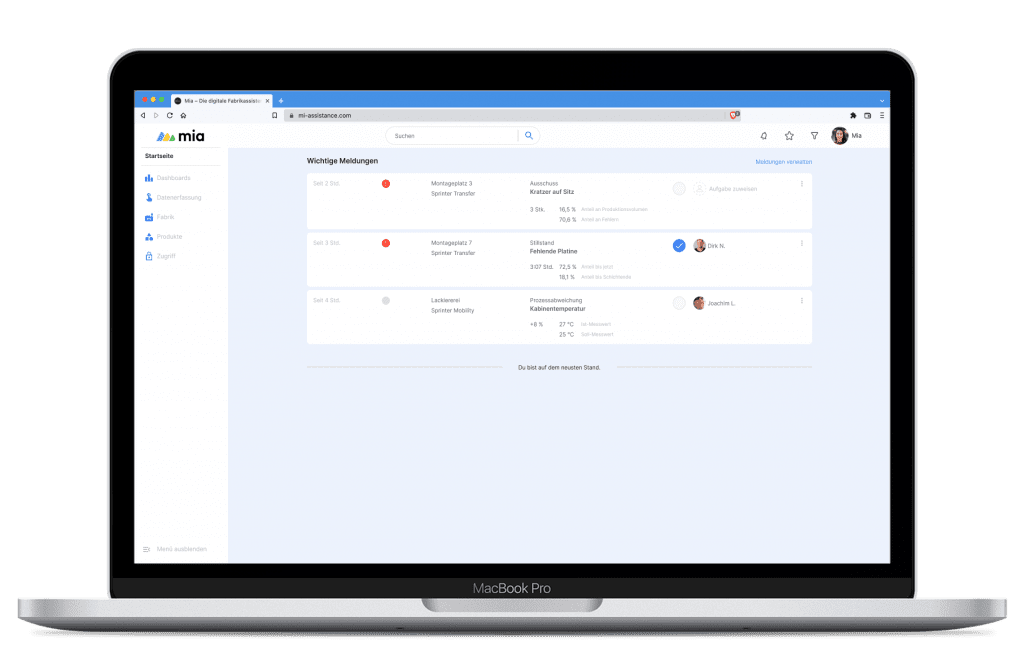

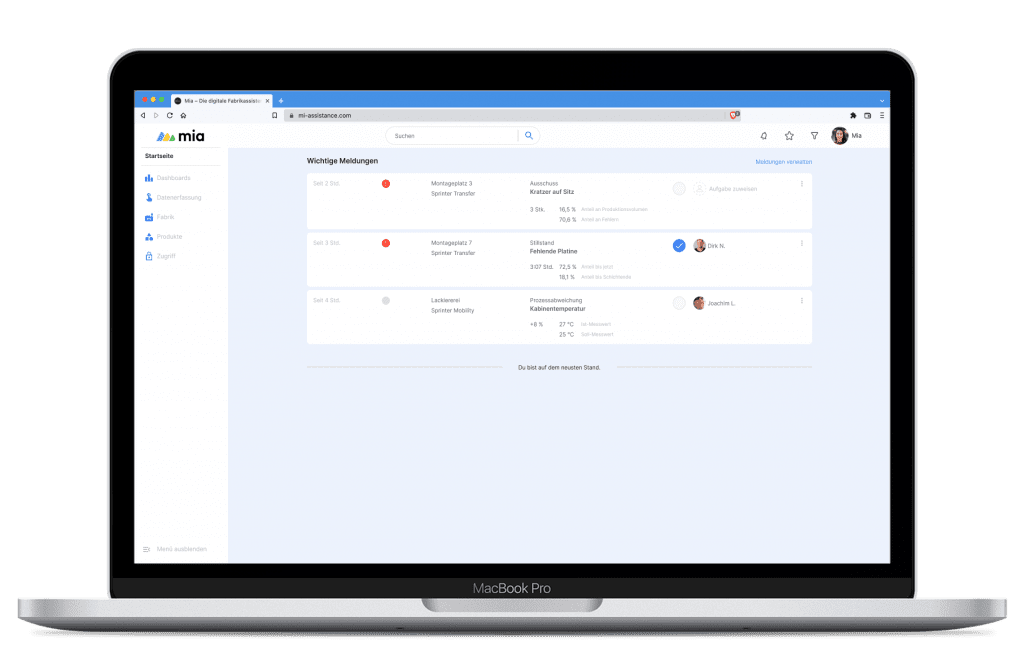

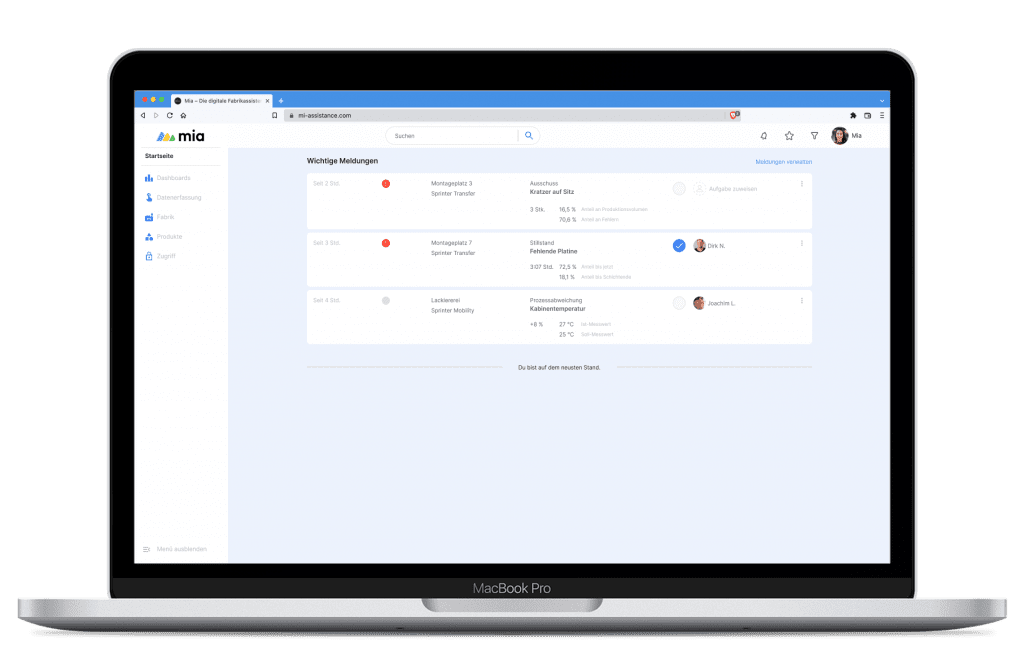

Simply react faster.

Never miss important events again to solve problems in time.

mia always informs you in good time via push notification. You decide on which topic, in which area and at which limit you are notified – of course also by e-mail or SMS.

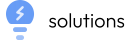

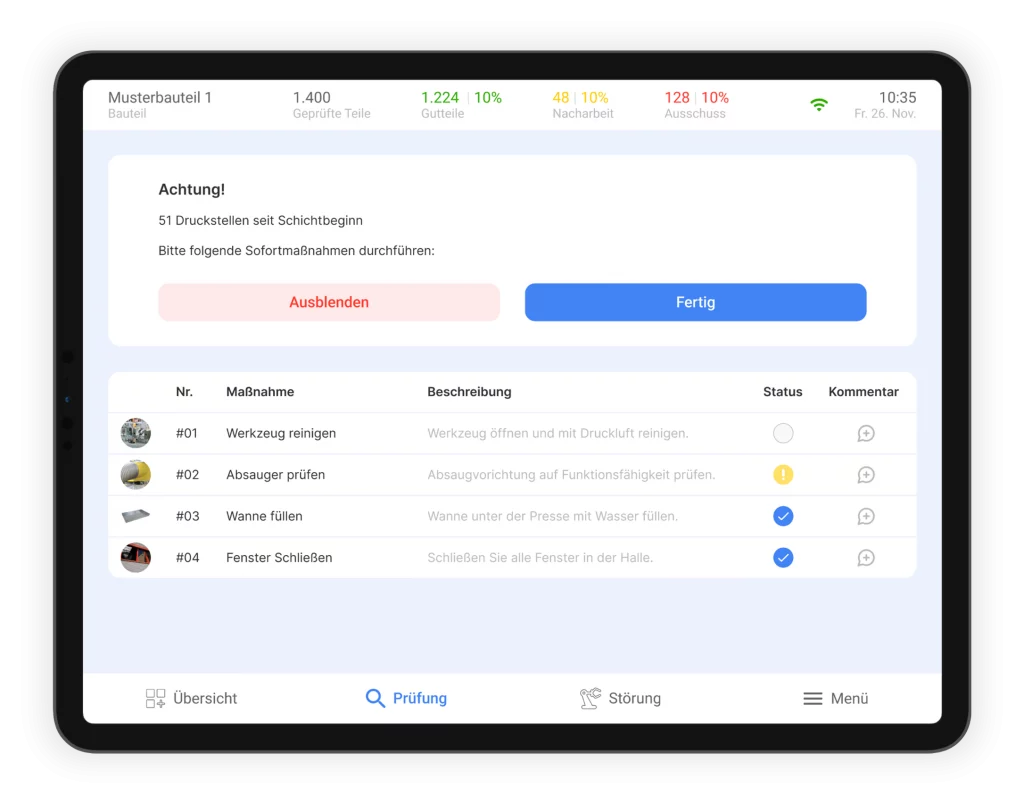

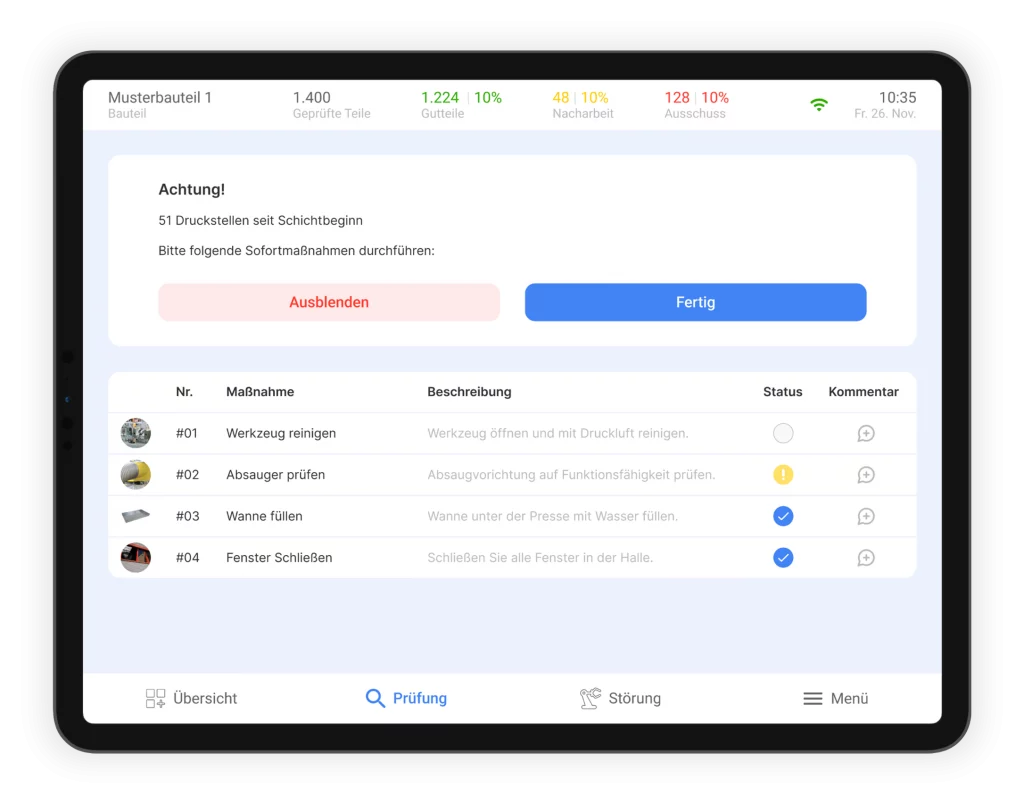

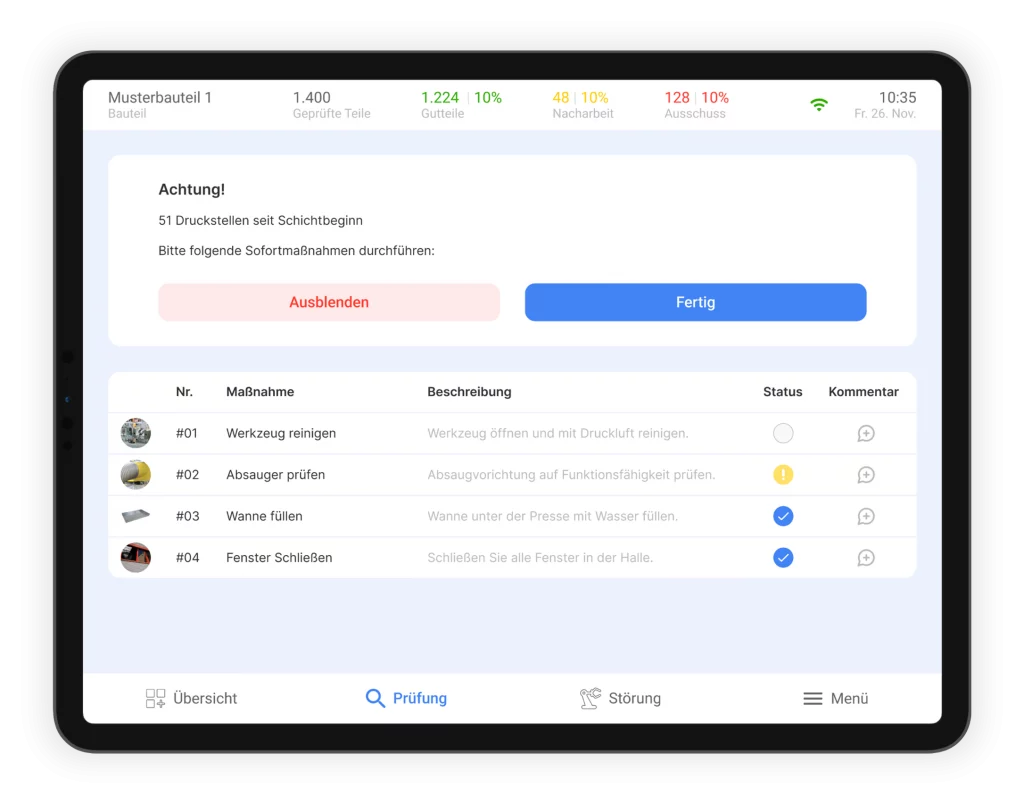

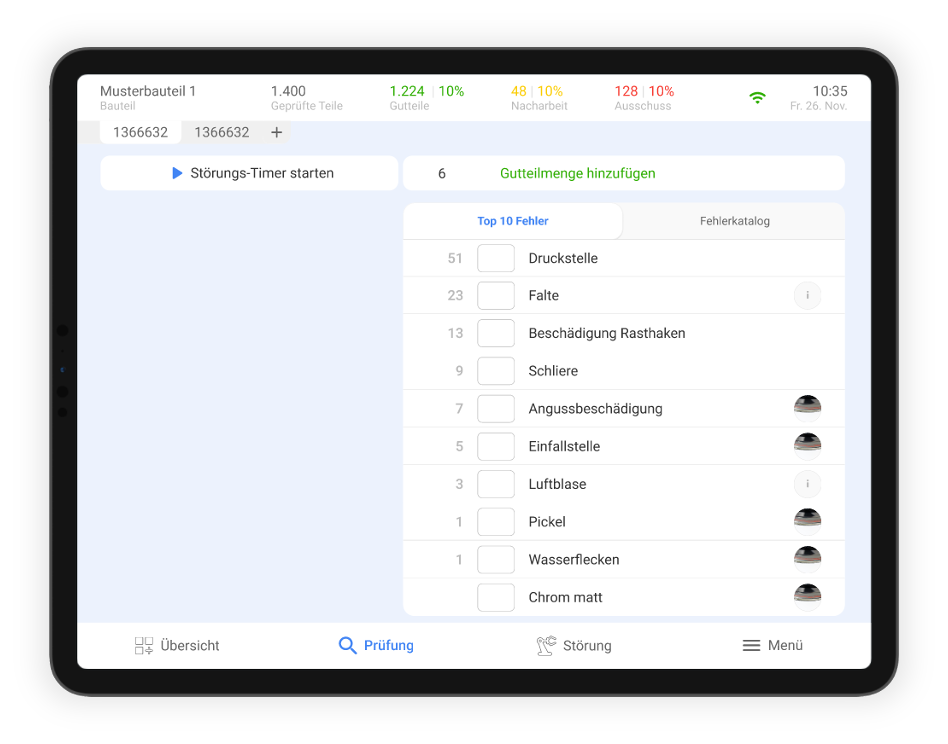

Solve known problems immediately.

Most quality or machine problems occur repeatedly. miasolutions offers workers a guide to the short-term implementation of immediate measures with a fault-related action catalogue. In this way, mia makes the knowledge of the most experienced workers available to everyone, especially when problems become acute.

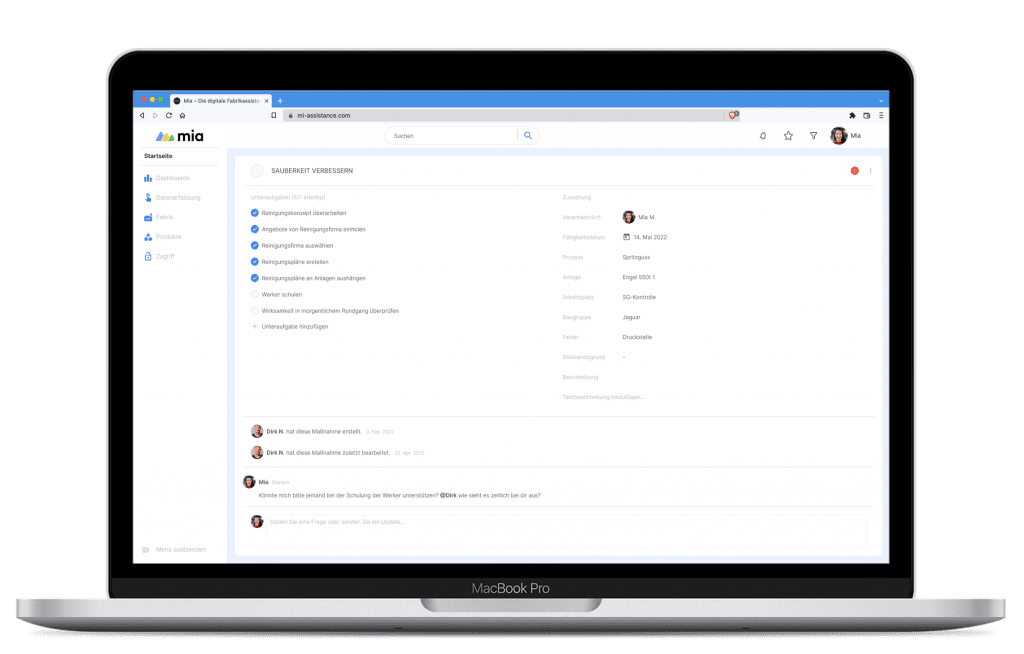

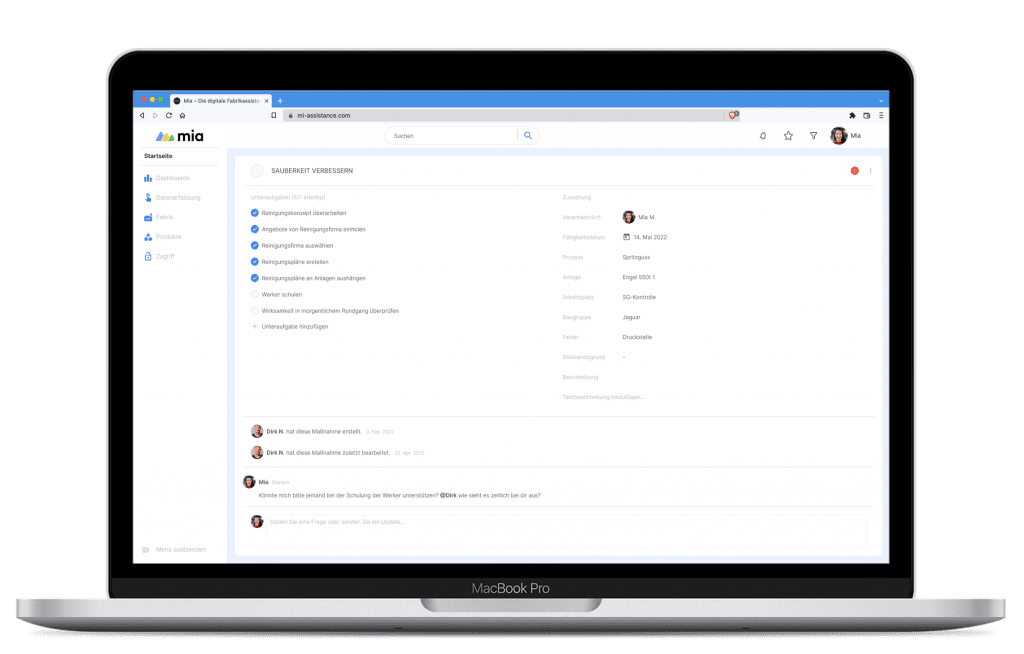

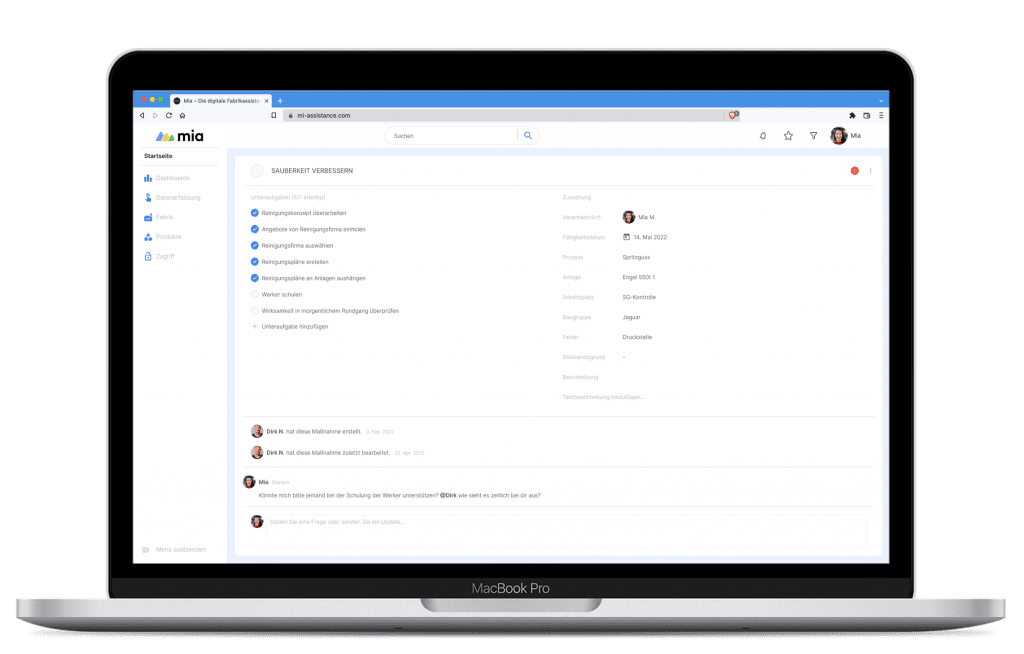

Work through tasks in a well-organised way as a team.

miataskboard offers the possibility to automatically transform problems into tasks and assign responsibility according to an escalation matrix. At the same time, you can use miataskboard in your daily production rounds to manage your shop floor.

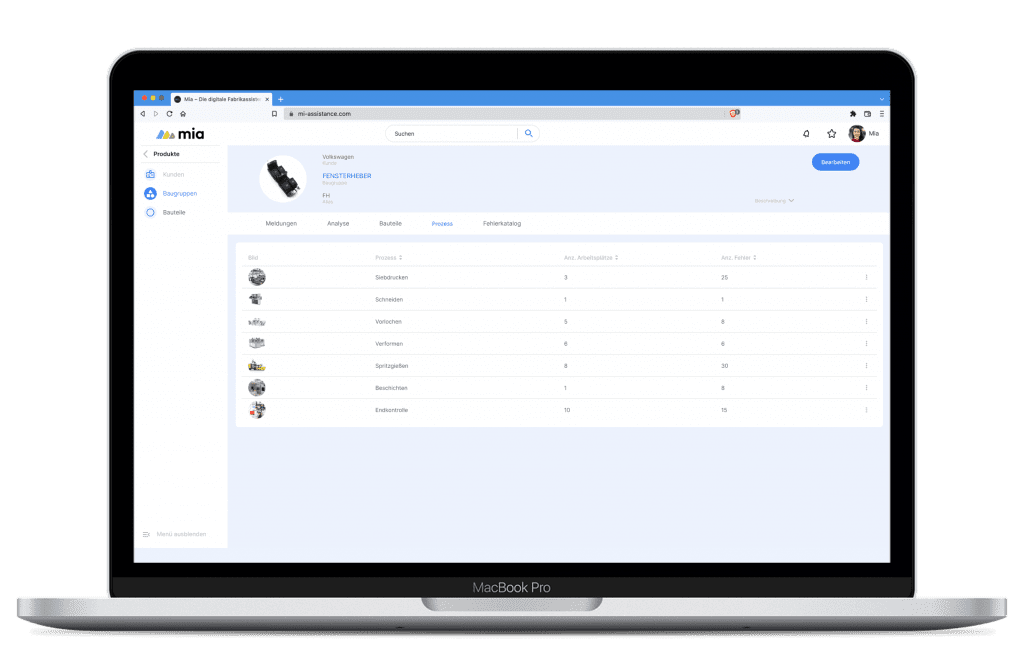

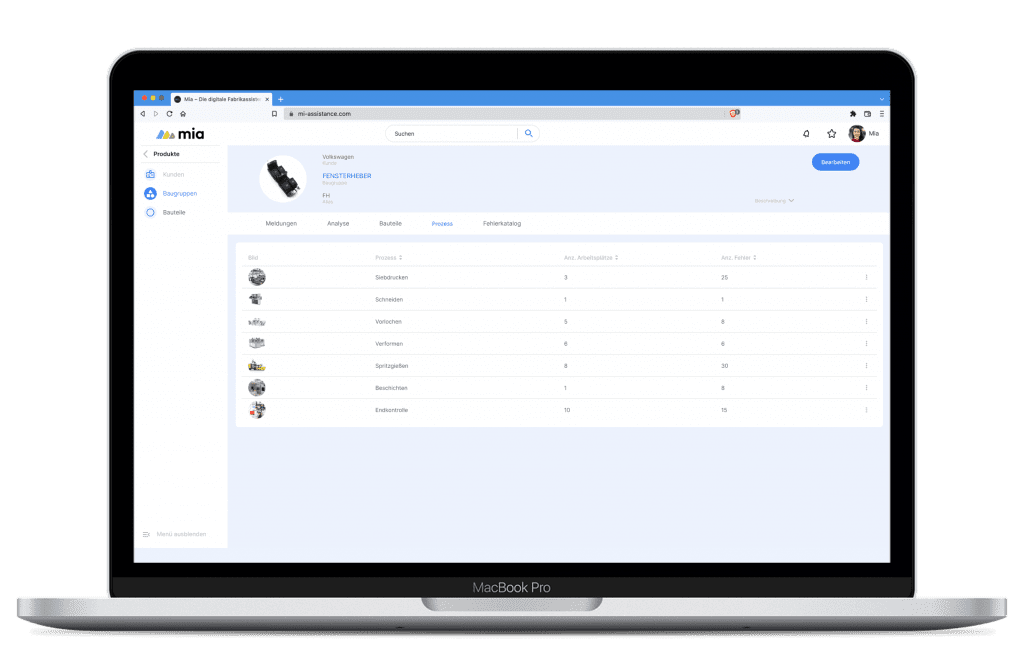

Detect deviations before they cause problems.

As a process expert in your field, you know which process parameters and measurement data are important for your process stability. miaprocess takes care of the rest by sending messages in case of deviations or even at an early stage by means of trend detection. At the same time, data is available retrospectively for analysis.

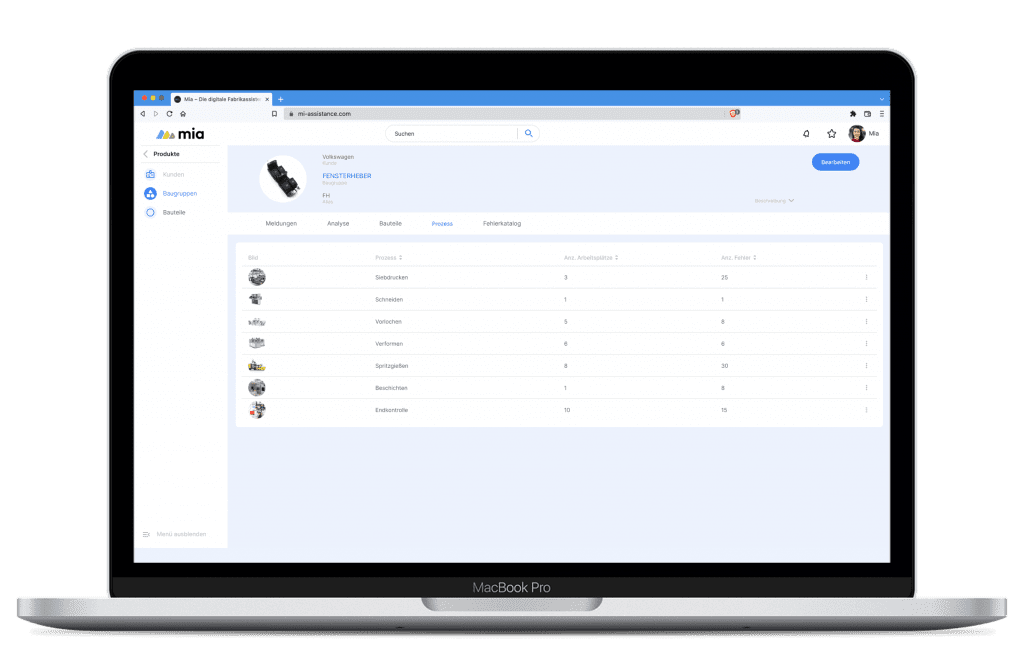

Easy management - No matter how complex your business is.

We place the highest value on simple and intuitive user development. This means, for example, that new product groups or entire plants can be created with just a few clicks. We offer admins maximum flexibility with complete standardisation.

One communication channel for all.

Workers often do not have their own e-mail box. With mia, department staff and workers can communicate with each other independently and purposefully. This is particularly useful for communication between the office and production.

Intelligent use of production-related documents.

No more running around and searching: Whether work instructions, limit sample catalogue or test plan, mia always provides your workers with the documents they need – at the moment they are needed.

Improve quality measurably.

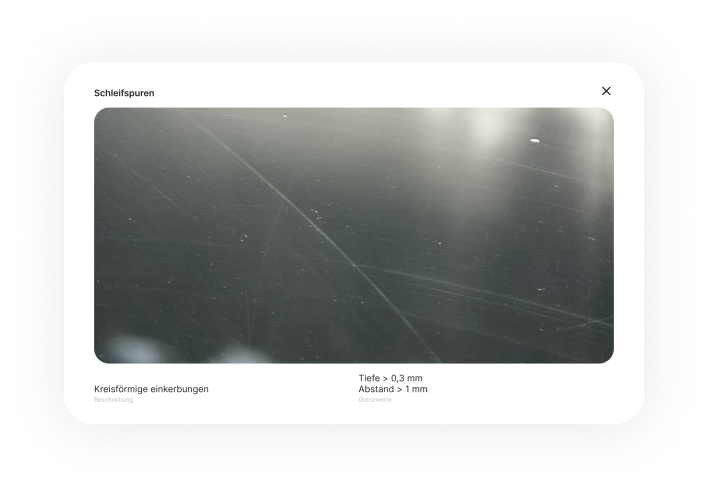

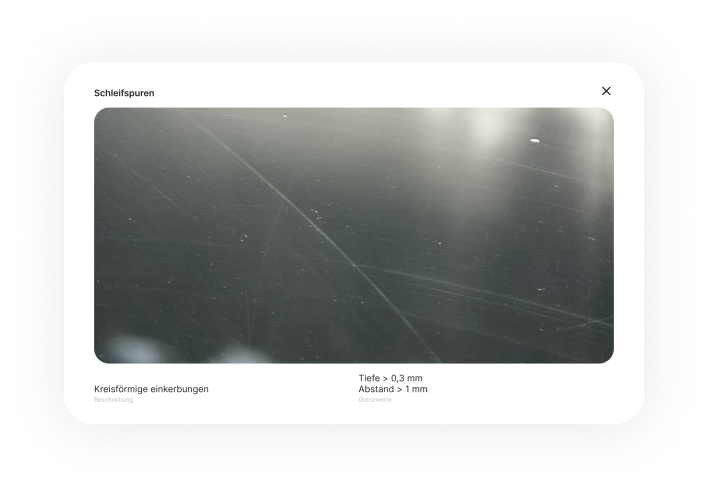

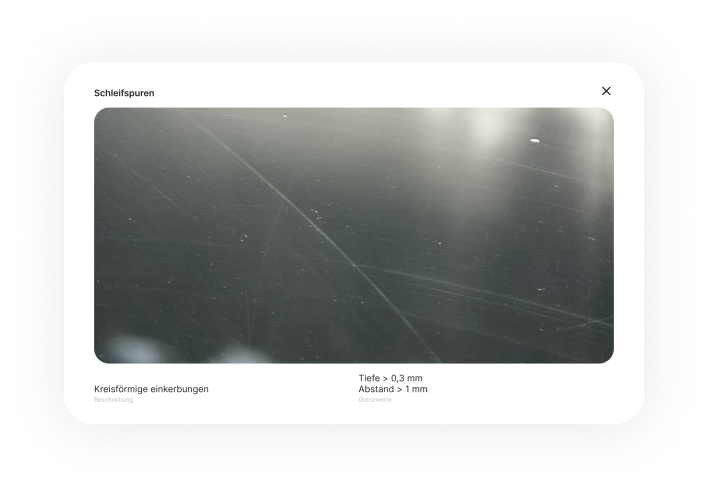

Some defects can already be identified digitally by image analysis or measurement. Nevertheless, there are many, especially surface defects, that can only be found by visual inspection. With miaquality, these can be recorded digitally without any additional effort for the inspectors.

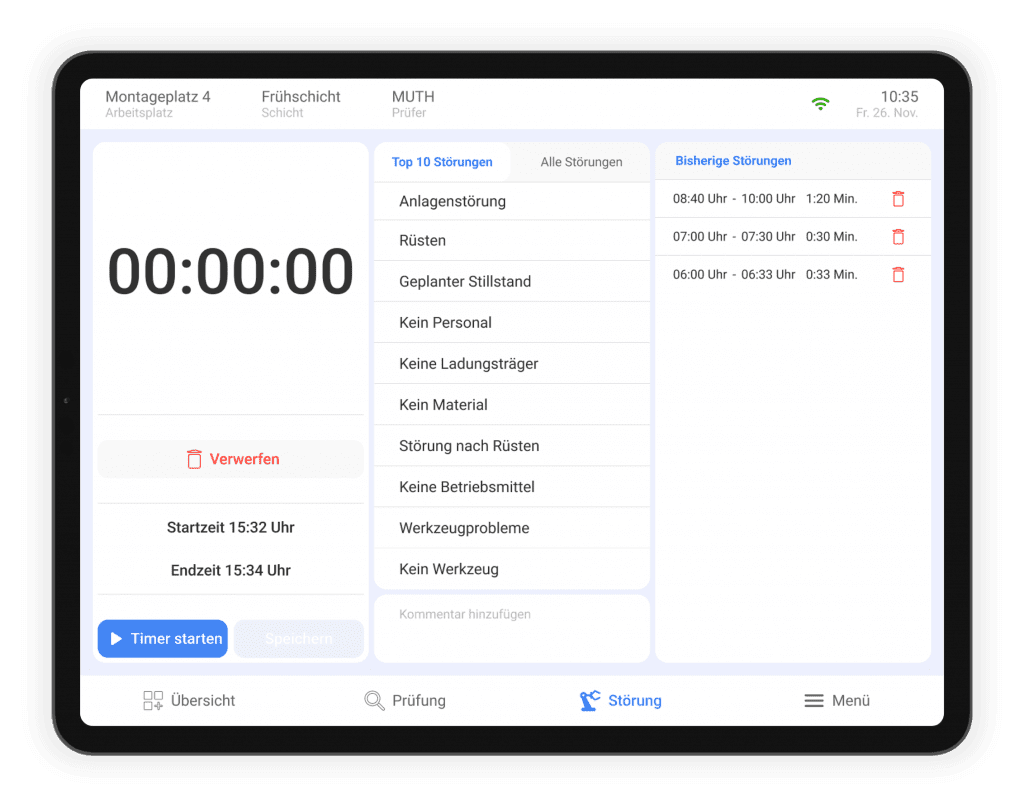

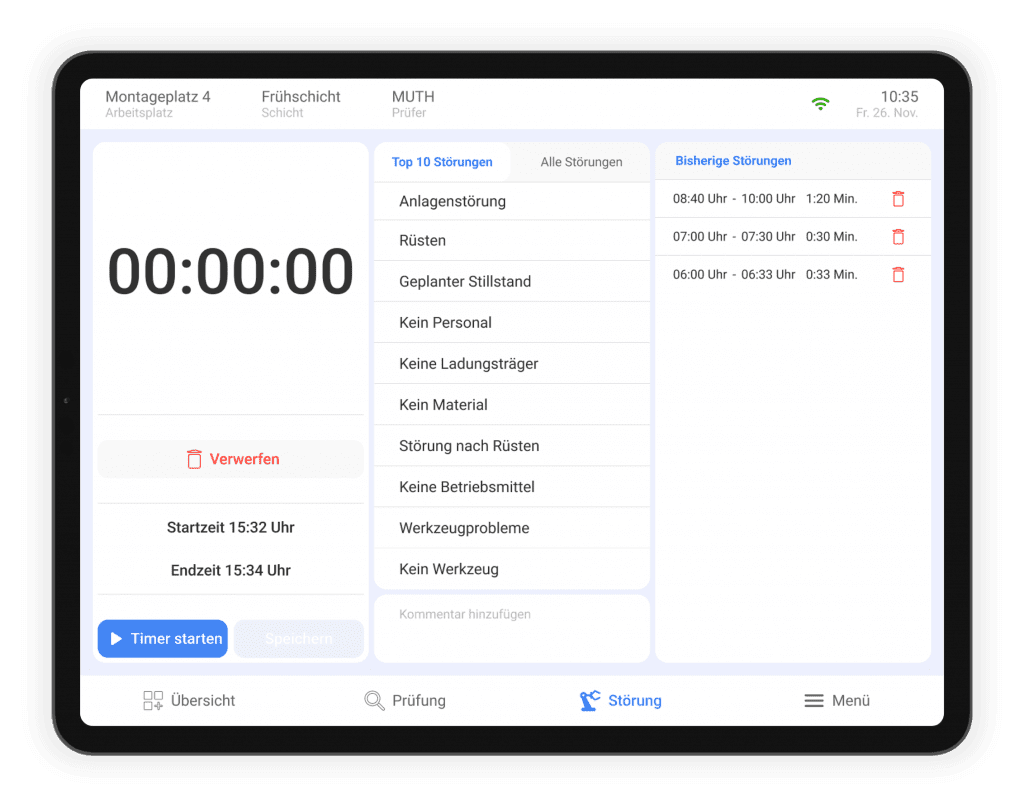

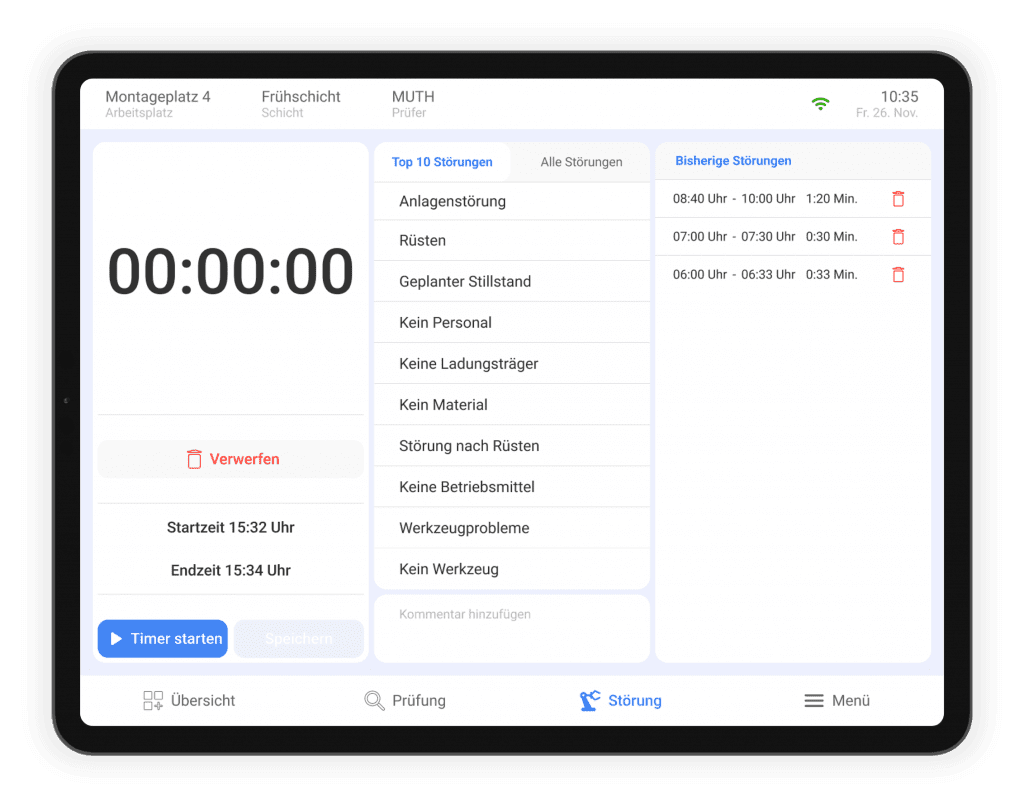

Make work processes measurable and optimise them.

Especially with longer assembly processes, set-up processes or processes with long downtimes, it is necessary to make processes measurable. With miadowntime, workers can record times for downtimes or sub-processes during their normal work with one click. This creates the data basis to turn the right screws for more efficient production.